YH2M8690 automatic positioning arc surface polishing machine

Keywords

Precision grinding, intelligent manufacturing technology, integrated solutions

Classification

Typical Machining Parts

Typical Machining Parts

|

|

|

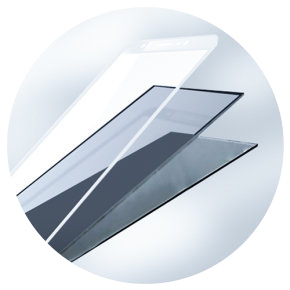

| 3D mobile phone cover glass | 2.5D phone glass |

Equipment Highlights

Equipment Highlights

● The equipment adopts continuous and uninterrupted polishing, loading and unloading, 3-station processing and 1-station loading and unloading.

● The equipment has 3 sets of independent servo lifting processing station upper plate system, through the motor current to feedback control the upper plate loading position.

● The rotation of the lower disc station is driven by a worm gear reducer of a frequency conversion motor and is positioned by a column pin.

● This machine is equipped with vacuum gas-liquid separation device, real-time monitoring of negative pressure, touch screen PLC control mode.

Technical parameters

Technical parameters

|

Project |

Unit |

Parameters |

|

Product Placement Tray |

mm |

12xφ420 |

|

Sweep Disc |

mm |

3xφ920 |

|

Upper plate lifting motor |

kW |

3x2.3 |

|

Lower disc self-rotating motor (variable frequency motor) |

kW |

4x2.2 |

|

Lower tray station conversion motor (variable frequency motor) |

kW |

4.0 |

|

Sweep disc motor (variable frequency motor) |

kW |

3x5.5 |

|

Upper plate stroke |

mm |

200 |

|

Lower tray station conversion speed |

rpm |

0-10 |

|

Rotation speed of lower disc |

rpm |

0-40 |

|

Sweep disc speed |

rpm |

0-280 |

|

Supply pressure |

Mpa |

0.6 |

|

vacuum adsorption pressure |

Kpa |

-75 |

|

Power supply pressure |

V |

Three-phase five-wire AC380V |

|

Total power of equipment |

kW |

36 |

|

Total mass of equipment |

kg |

4900 |

|

Equipment size |

mm |

2540x2540x2600 |

Previous article

Previous article

recommend products